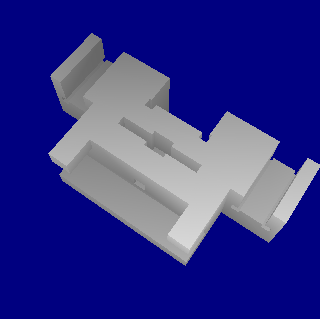

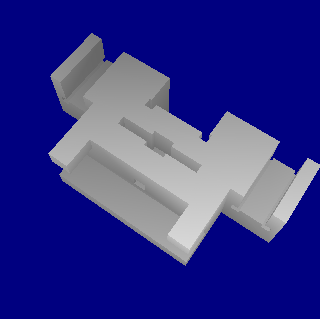

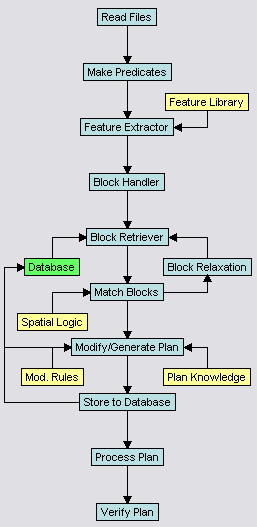

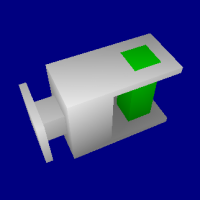

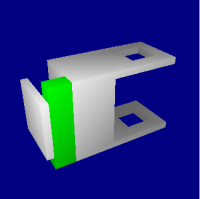

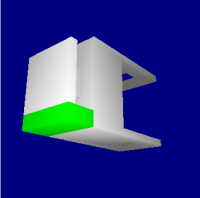

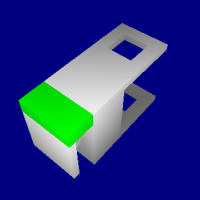

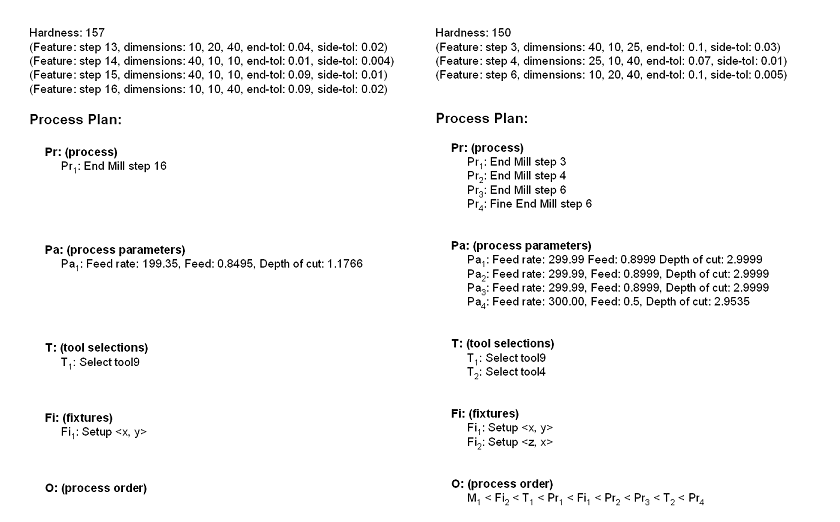

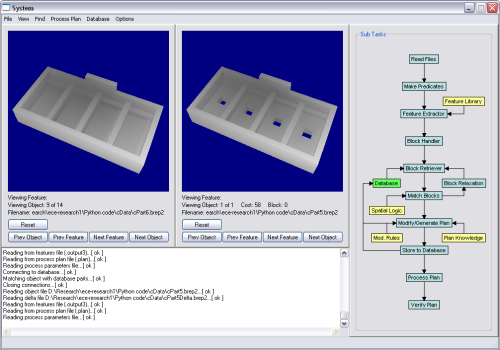

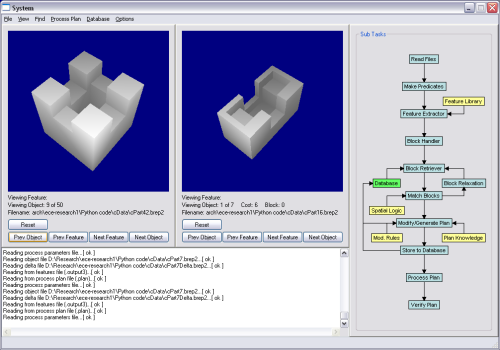

Setup: <y, x>

Select tool: 8

Do operation: End Mill slot 235

Select tool: 9

Do operation: End Mill blind-slot 63

Select tool: 4

Do operation: Fine End Mill blind-slot 63

Select tool: 17

Do operation: Drill pocket 44

Select tool: 7

Do operation: End Mill pocket 44

Select tool: 16

Do operation: Drill hole 49

Do operation: Drill hole 50

Select tool: 6

Do operation: End Mill hole 49

Do operation: End Mill hole 50

Setup: <y, -z>

Select tool: 15

Do operation: End Mill slot 212

Select tool: 16

Do operation: Drill hole 47

Do operation: Drill hole 48

Select tool: 6

Do operation: End Mill hole 47

Do operation: End Mill hole 48

Select tool: 1

Do operation: Fine End Mill hole 47

Do operation: Fine End Mill hole 48

Setup: <x, y>

Select tool: 8

Do operation: End Mill slot 213

Do operation: End Mill slot 239

Setup: <x, -y>

Select tool: 16

Do operation: Drill hole 45

Do operation: Drill hole 46

Select tool: 6

Do operation: End Mill hole 45

Do operation: End Mill hole 46

Setup: <z, -x>

Select tool: 15

Do operation: End Mill step 306

Setup: <z, x>

Select tool: 15

Do operation: End Mill step 313

|

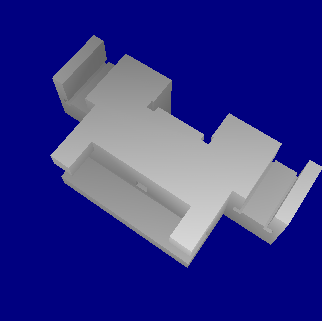

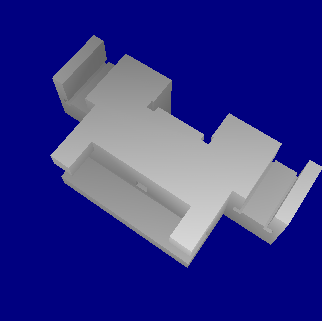

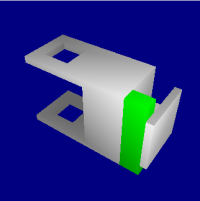

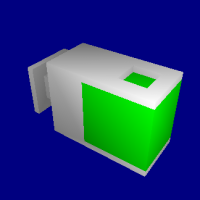

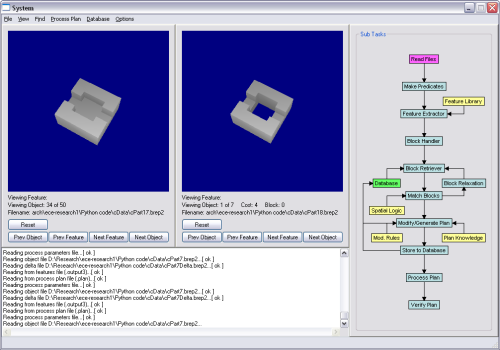

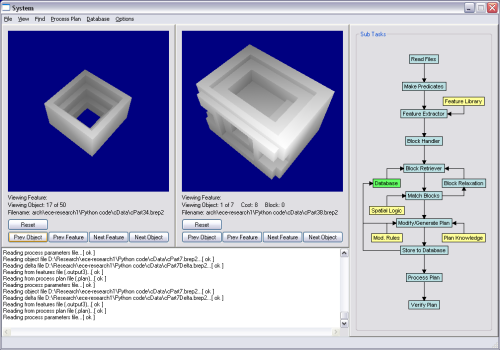

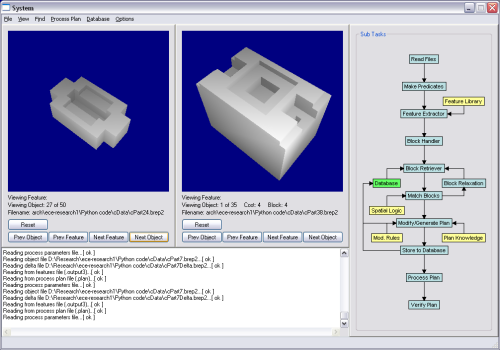

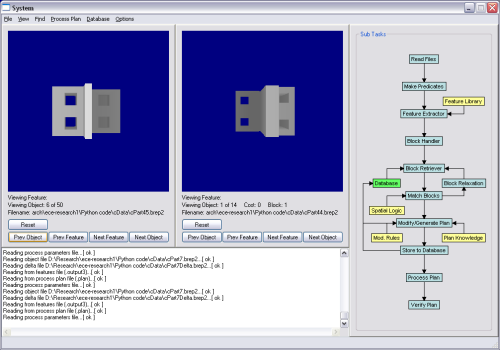

Setup: <x, y>

Select tool: 16

Do operation: Drill pocket 21

Select tool: 17

Do operation: Drill pocket 19

Select tool: 8

Do operation: End Mill slot 272

Do operation: End Mill slot 271

Select tool: 6

Do operation: End Mill pocket 21

Select tool: 7

Do operation: End Mill pocket 19

Select tool: 16

Do operation: Drill hole 74

Do operation: Drill hole 75

Select tool: 6

Do operation: End Mill hole 74

Do operation: End Mill hole 75

Setup: <y, z>

Select tool: 8

Do operation: End Mill slot 264

Select tool: 9

Do operation: End Mill blind-slot 92

Select tool: 4

Do operation: Fine End Mill blind-slot 92

Select tool: 17

Do operation: Drill pocket 73

Select tool: 7

Do operation: End Mill pocket 73

Select tool: 16

Do operation: Drill hole 78

Do operation: Drill hole 79

Select tool: 6

Do operation: End Mill hole 78

Do operation: End Mill hole 79

Select tool: 1

Do operation: Fine End Mill hole 79

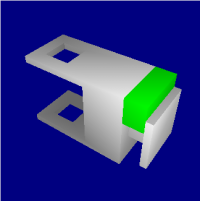

Setup: <y, -z>

Select tool: 15

Do operation: End Mill slot 245

Select tool: 16

Do operation: Drill hole 76

Do operation: Drill hole 77

Select tool: 6

Do operation: End Mill hole 76

Do operation: End Mill hole 77

Setup: <z, -x>

Select tool: 15

Do operation: End Mill step 339

Select tool: 5

Do operation: Fine End Mill step 339

Setup: <z, x>

Select tool: 15

Do operation: End Mill step 349

|